In precision metalworking, selecting the correct grinding wheel is critical for achieving efficient material removal, extended tool life, and optimal surface finish. Whether you're grinding carbide end mills, regrinding drills, or shaping complex cutting tools, understanding how to choose the right wheel based on bond type, abrasive grain, and application method is essential.

Understanding Grinding Wheel Bonds for Metalworking

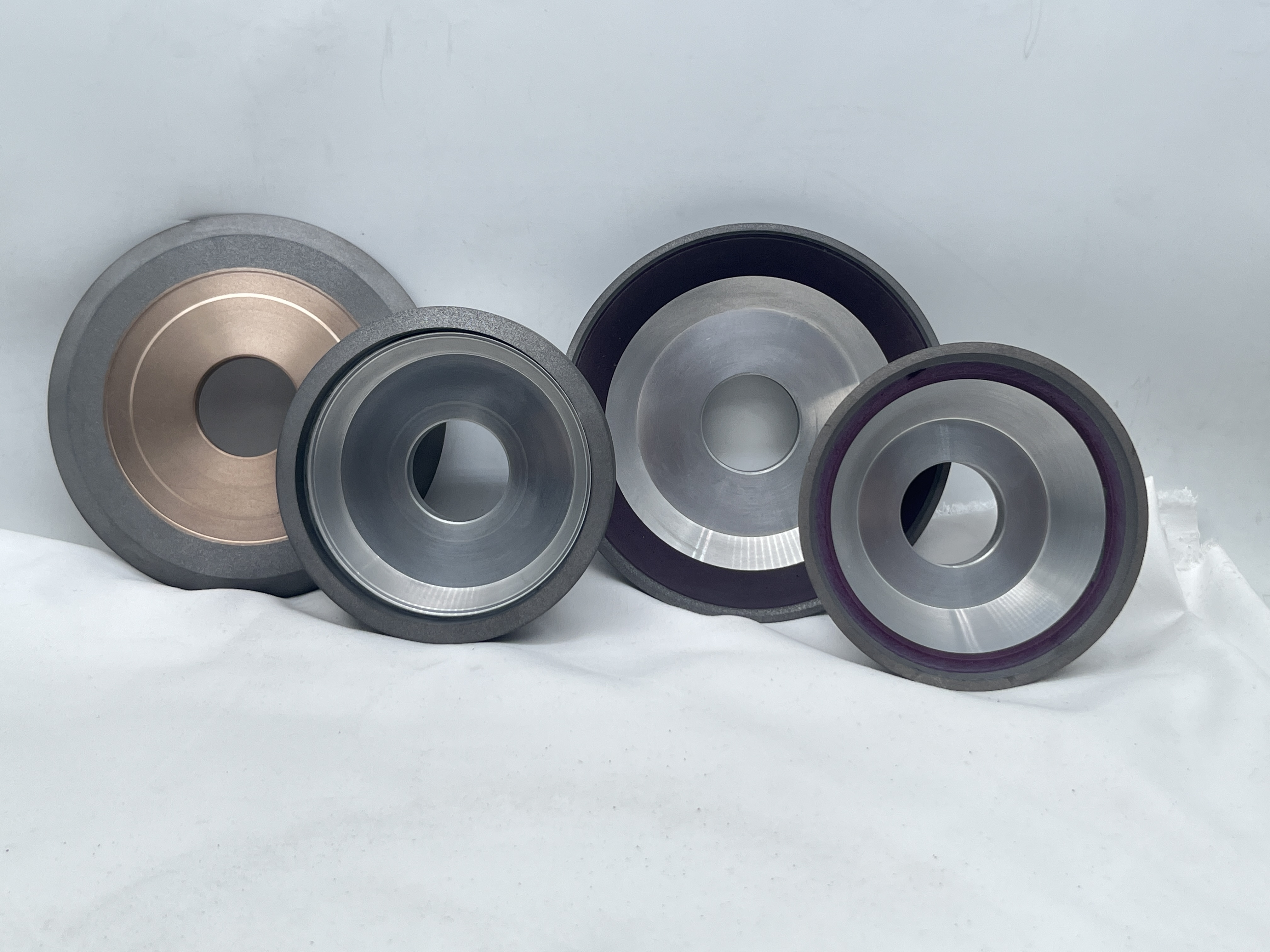

The bond in a grinding wheel plays a key role in holding abrasive grains together and determining how the wheel behaves under pressure and heat. For tool grinding in the metalworking industry—particularly on tungsten carbide cutting tools—the two most widely used bonds are:

Resin Bond

Resin bond wheels are known for their excellent cutting performance and self-sharpening ability. They are ideal for applications requiring a fine surface finish and high grinding efficiency, such as end face grinding, fluting, and peripheral grinding of carbide tools. Resin bond wheels also reduce thermal damage, making them perfect for delicate or complex tool geometries.

Hybrid (Metal-Resin) Bond

Hybrid bond wheels combine the toughness of metal bonds with the sharpness and elasticity of resin bonds. These wheels offer longer life, high edge retention, and consistent form accuracy—especially suitable for slotting, grooving, and external cylindrical grinding of carbide tools. They are often used in CNC tool grinders for automated regrinding tasks, delivering both efficiency and repeatability.

Selecting the Right Abrasive for Hard Metal Grinding

The two main types of abrasives used for metalworking grinding wheels are:

Diamond Abrasive

Diamond is the preferred abrasive for carbide tool grinding due to its unmatched hardness and thermal conductivity. Diamond grinding wheels deliver fast stock removal and fine finishes on non-ferrous materials such as tungsten carbide, ceramics, and cermets.

CBN (Cubic Boron Nitride)

While not suitable for carbide, CBN abrasives are ideal for grinding hardened steels and ferrous alloys. In tooling environments that involve steel substrates or HSS-based cutting tools, CBN wheels offer excellent thermal resistance and dimensional control.

Grinding Applications in Metal Cutting Tool Production

In the manufacturing and regrinding of carbide end mills, drills, and profile tools, different grinding operations are performed using customized wheels:

Slot Grinding / Gashing

Used to create the initial cutting edge on drills and end mills. Resin or hybrid bond wheels are selected based on depth and tool material.

Flute Grinding

Critical for chip evacuation and cutting efficiency. This operation requires wheels with good form retention and sharp cutting behavior, typically hybrid bond diamond wheels.

Peripheral or OD Grinding

External diameter grinding is used for sizing and shaping tool blanks. High-strength hybrid bond wheels are ideal here, maintaining edge geometry and surface integrity.

Relief or Clearance Grinding

Grinding of clearance angles to reduce friction during cutting. This operation demands precision wheels that maintain sharp cutting profiles under low grinding pressure.

Trust Ruizuan Diamond Tools for Professional Metalworking Solutions

At Zhengzhou Ruizuan Diamond Tools Co., Ltd., we specialize in producing diamond and CBN grinding wheels engineered for high-performance carbide and HSS tool grinding. With over 20 years of manufacturing expertise, we offer custom-designed solutions to support industries including aerospace, automotive, mold & die, woodworking, and general metalworking.

Looking for Grinding Efficiency and Precision?

Contact us today for expert support in choosing the perfect grinding solution for your carbide or HSS tool applications. Let us help you reduce cycle times, extend tool life, and boost overall productivity.

Post time: Jun-13-2025