In the competitive landscape of B2B manufacturing, the bulk procurement of diamond grinding wheels is a strategic decision that can significantly impact production costs, efficiency, and the quality of end - products. As a leading provider in the abrasive tools industry, Zhengzhou Ruizuan Diamond Tools understands the intricacies involved in large - scale purchases. This guide is designed to equip B2B buyers with essential tips and insights, from product evaluation to supplier selection, ensuring successful and cost - effective bulk acquisitions.

Understanding Your Application Requirements

1. Workpiece Material Analysis

Hard and Brittle Materials: When machining materials such as ceramics, glass, and carbide, diamond grinding wheels are the ideal choice due to their extreme hardness. For example, in the semiconductor industry, where precision is crucial for wafer processing, high - quality diamond wheels can achieve the necessary sub - micron tolerances.

Ferrous vs. Non - Ferrous Metals: While diamond is highly effective for non - ferrous metals, its reactivity with iron at high temperatures limits its use with ferrous materials. In such cases, cubic boron nitride (CBN) wheels may be a better alternative. B2B buyers must clearly define the materials they will be working with to select the most suitable diamond grinding wheels.

2. Grinding Process Requirements

Roughing vs. Finishing Operations: Different grinding stages demand varying wheel characteristics. For roughing, wheels with coarser grit sizes (e.g., 36 - 60#) are preferred for rapid material removal. Finishing operations, on the other hand, require finer grits (180 - 600#) to achieve smooth surface finishes. Understanding the proportion of roughing and finishing tasks in your production process will help determine the appropriate mix of wheel grits for bulk procurement.

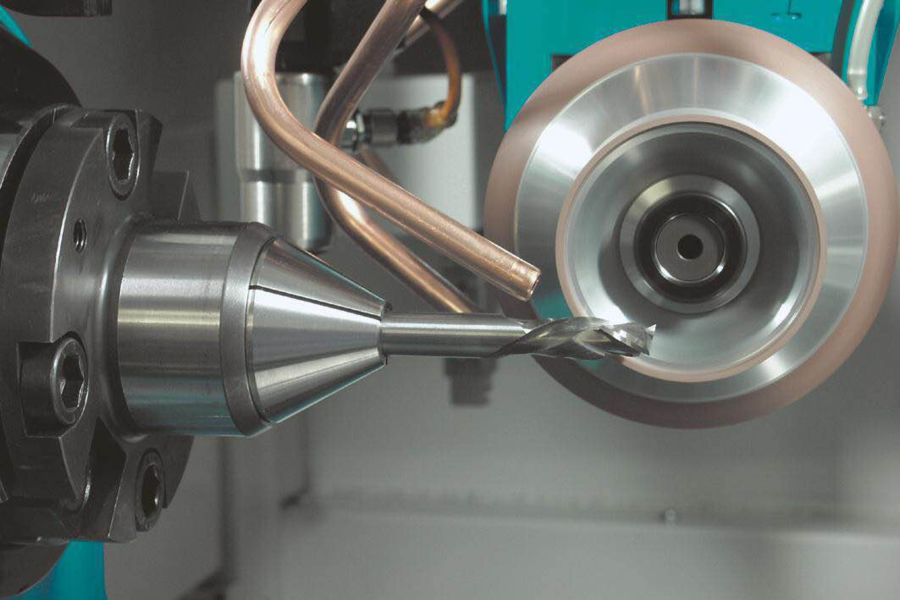

Grinding Method: Whether it's surface grinding, cylindrical grinding, or internal grinding, each method has specific requirements for wheel shape, size, and bond type. For instance, surface grinding may benefit from wheels with a flat profile, while cylindrical grinding requires wheels with precise diameters and thicknesses.

Evaluating Product Quality and Performance

1. Abrasive Grain Quality

Grain Purity and Consistency: High - quality diamond grains should have consistent size, shape, and purity. Impurities or variations in grain size can lead to uneven cutting performance and reduced wheel life. At Ruizuan, we source only the finest diamond grains and subject them to rigorous quality control checks to ensure uniformity.

Grain Bonding Strength: The bond that holds the diamond grains in place is crucial for wheel durability. A strong bond ensures that the grains remain securely attached during grinding, preventing premature grain loss. Our diamond grinding wheels feature advanced bonding technologies that optimize the balance between grain retention and self - sharpening properties.

2. Wheel Manufacturing Standards

ISO Certification: Look for suppliers whose products comply with international standards such as ISO 9001:2015. This certification indicates that the manufacturer has implemented a comprehensive quality management system, ensuring consistent product quality. All of our diamond grinding wheels are produced in ISO - certified facilities, guaranteeing reliability and performance.

Testing and Inspection: Reputable suppliers conduct extensive testing on their products, including hardness testing, balance testing, and performance trials. Ask for test reports and documentation to verify the quality of the wheels you plan to purchase in bulk.

Bulk procurement of diamond grinding wheels is a complex process that requires careful consideration of application requirements, product quality, supplier selection, and cost - effectiveness. By following the tips outlined in this guide, B2B buyers can make informed decisions that optimize their procurement strategies, enhance production efficiency, and drive business success.

At Zhengzhou Ruizuan Diamond Tools, we are committed to providing B2B customers with top - quality diamond grinding wheels, competitive pricing, and exceptional customer service.

Post time: Jul-03-2025