Polycrystalline Diamond (PCD) and Polycrystalline Cubic Boron Nitride (PCBN) tools have revolutionized precision machining with their exceptional hardness, wear resistance, and long service life. However, maximizing their performance requires specialized grinding solutions. At Zhengzhou Ruizuan Diamond Tools, we've engineered vitrified diamond grinding wheels specifically for PCD and PCBN tool manufacturing—a choice backed by decades of research and industrial validation. This guide explains why vitrified bonds outperform alternatives, their applications, and how to select the optimal wheel for your needs.

Why Vitrified Diamond Wheels Excel for PCD/PCBN Tool Grinding

Vitrified bonds—composed of ceramic materials like feldspar, kaolin, and glass frits—offer unique advantages when machining super-hard materials like PCD (8,000-10,000 HV) and PCBN (4,500-5,500 HV):

1. Superior Thermal Stability

Vitrified bonds maintain structural integrity at temperatures up to 1,000°C, critical for grinding PCD, which begins to degrade above 700°C. This stability:

Prevents thermal damage to PCD's diamond grain structure

Reduces micro-cracking in PCBN substrates

Maintains consistent grinding performance during extended operations

2. Controlled Porosity and Chip Evacuation

Our proprietary vitrified bond formulation features 18-25% porosity, engineered to:

Efficiently remove diamond and carbide chips during grinding

Facilitate coolant flow to the cutting zone, reducing friction and heat

Prevent wheel loading, which compromises surface finish

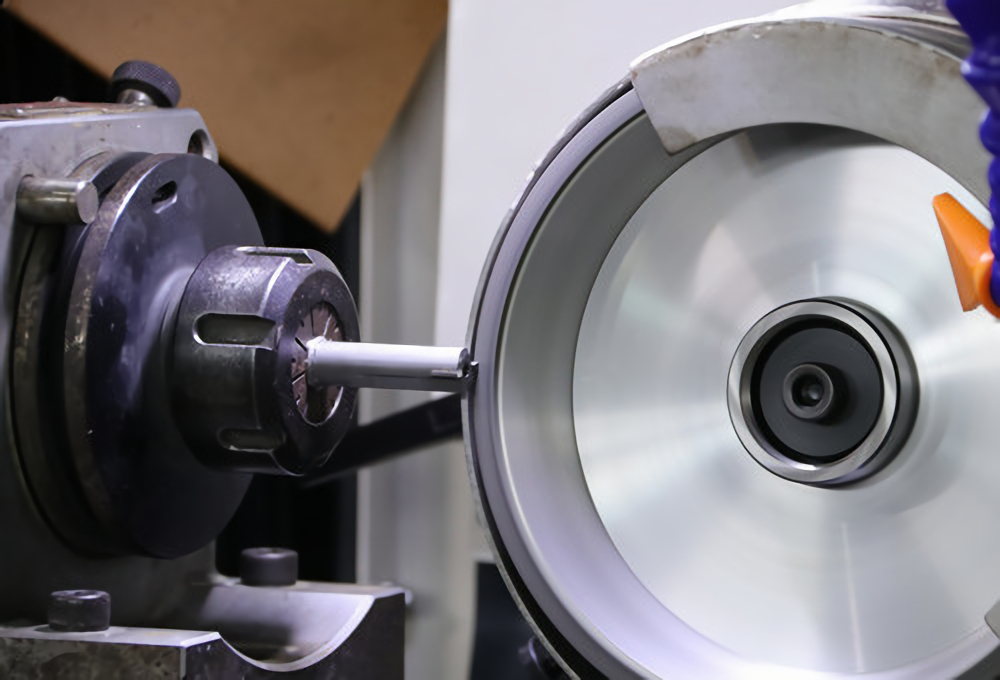

3. Exceptional Shape Retention

Vitrified bonds offer 30-40% higher rigidity than resin bonds, ensuring:

Precise maintenance of tool geometries (relief angles, cutting edges)

Consistent dimensional accuracy (±0.002mm) across production runs

Reduced dressing frequency, lowering production costs

Applications: Where Vitrified Diamond Wheels Shine

Vitrified diamond grinding wheels deliver unmatched results across PCD/PCBN tool categories:

1. PCD Cutting Tools

Woodworking Tools: Achieve mirror-finish edges on PCD-tipped saw blades and router bits, reducing material pull and improving surface quality in hardwood processing.

Automotive Machining: Precision-grind PCD inserts for aluminum cylinder head machining, maintaining tight tolerances on cutting edges for 50,000+ components.

Aerospace Components: Produce PCD drills and end mills for composite material machining, ensuring burr-free holes in carbon fiber reinforced polymers (CFRP).

2. PCBN Tool Applications

Hardened Steel Turning: Grind PCBN inserts for machining bearing races (58-62 HRC), achieving edge sharpness that extends tool life by 40% compared to conventionally ground alternatives.

Cast Iron Machining: Create precise chip breakers on PCBN tools for gray and ductile cast iron applications, improving chip control and surface finish.

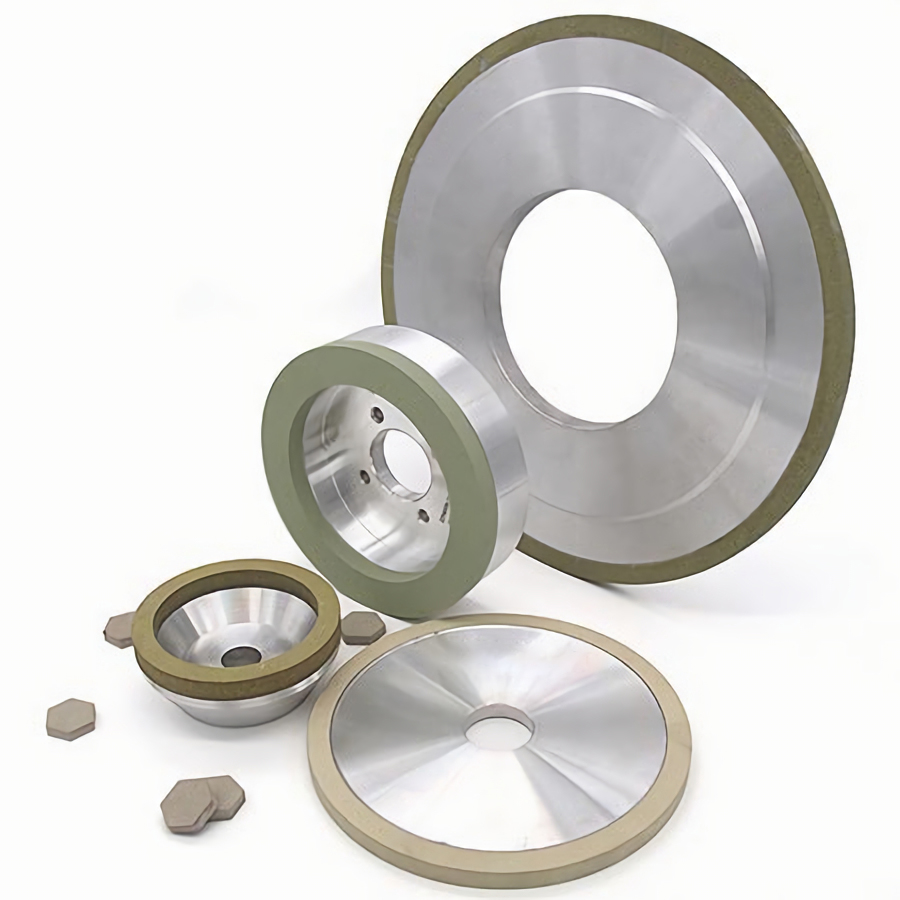

Ruizuan's Vitrified Diamond Solutions for PCD/PCBN Tools

At Zhengzhou Ruizuan, our vitrified diamond grinding wheels for PCD/PCBN tools feature:

Advanced Ceramic Formulation: Proprietary vitrified bond (Patent No. CN 112373652B) with optimized thermal conductivity

Precision Grain Distribution: Uniform diamond placement ensuring consistent wear and cutting action

Custom Engineering: Tailored solutions for specific tool geometries, from inserts to complex form tools

Quality Assurance: Each wheel undergoes laser profilometry and balance testing to ensure <0.003mm runout

Vitrified diamond grinding wheels represent the pinnacle of technology for PCD and PCBN tool manufacturing, offering unmatched precision, thermal stability, and consistency. At Zhengzhou Ruizuan Diamond Tools, we combine material science expertise with industrial experience to deliver solutions that maximize tool performance while reducing production costs.

Post time: Jul-28-2025