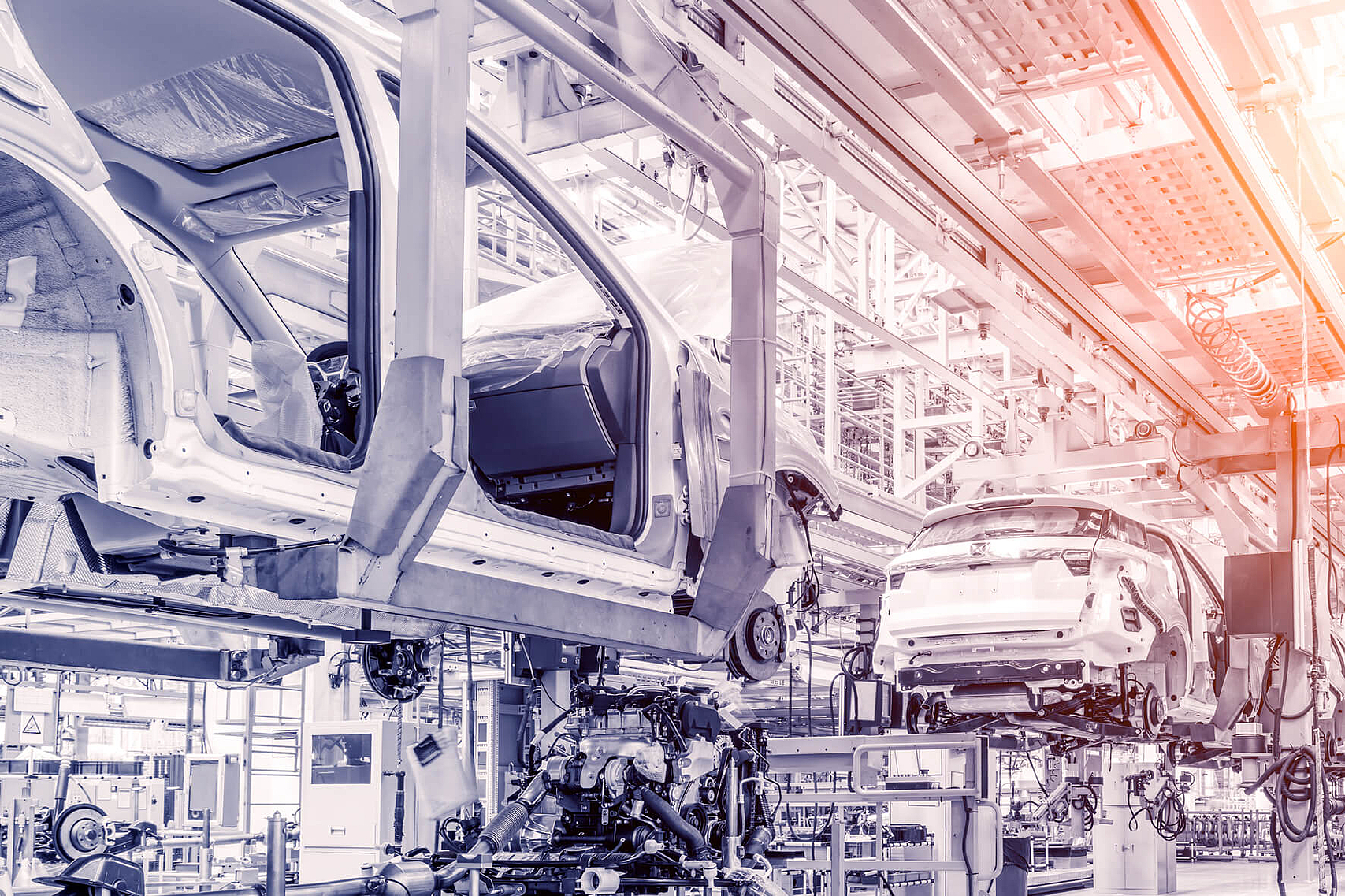

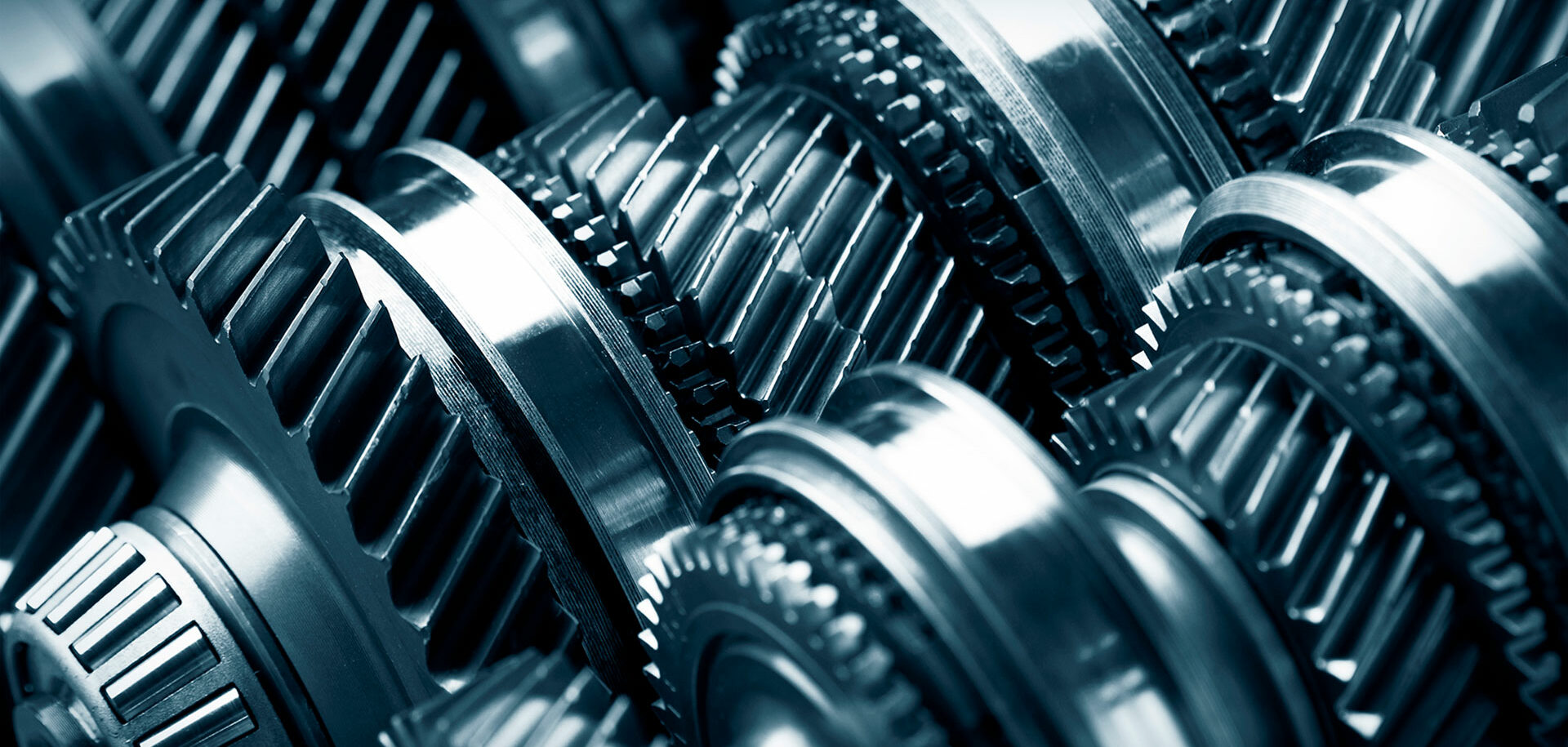

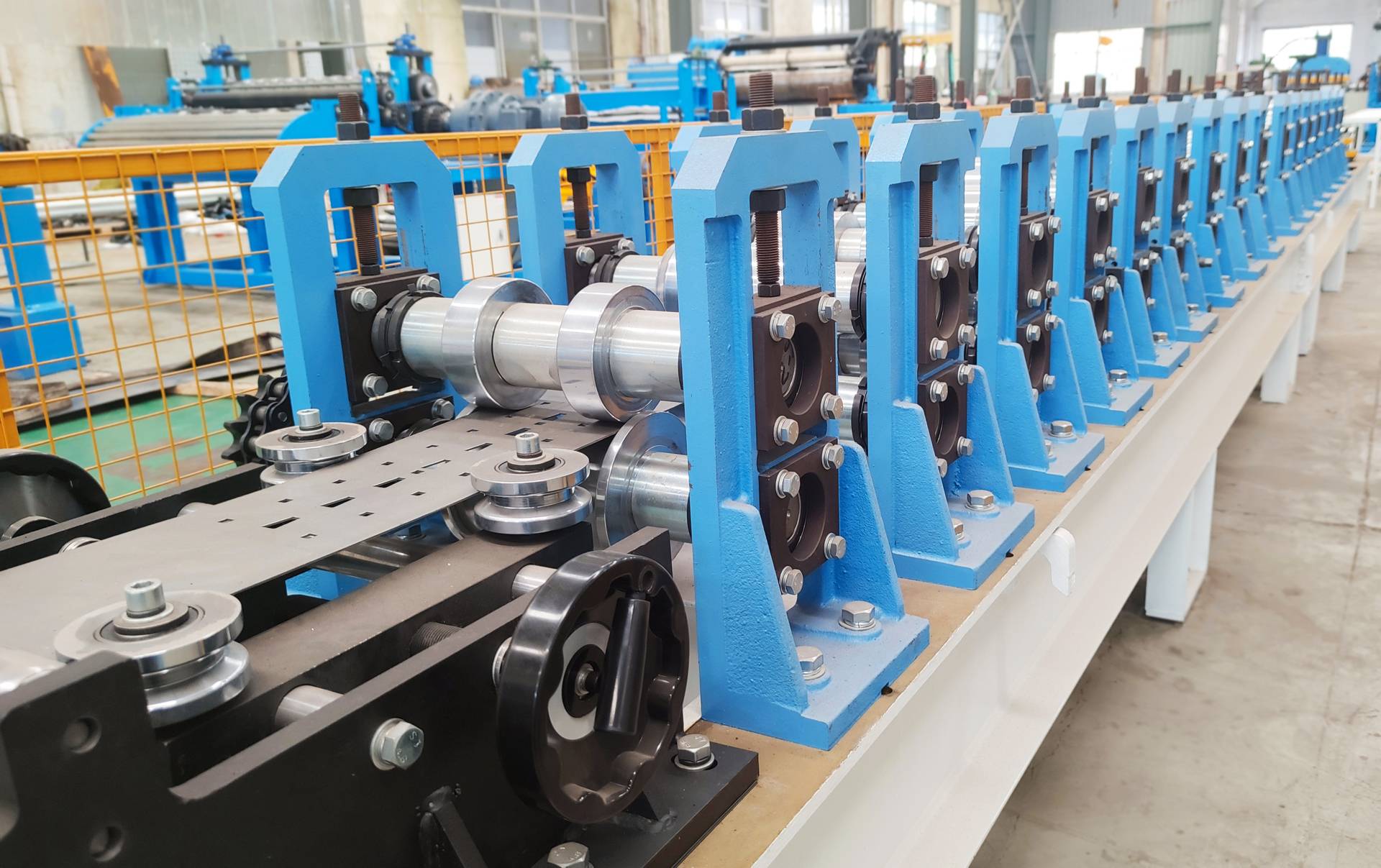

CBN materials, known as cubic boron nitride, have revolutionized various industries with their superior properties and exceptional performance. Their successful application in diverse fields such as automobile manufacturing, machinery industry, bearing and gear industry, roll industry, and aerospace industry has made them an indispensable material for commercial export. Let us explore the incredible applications of CBN materials in these sectors.

In conclusion, the applications of CBN materials across industries are vast and significant. Their various advantageous properties, including high hardness, wear resistance, thermal stability, and low friction, make them indispensable in automobile manufacturing, machinery industry, bearing and gear industry, roll industry, and aerospace industry. The use of CBN materials results in enhanced durability, improved performance, and reduced manufacturing costs, thus benefiting both manufacturers and end-users. As an official commercial export, the global market for CBN materials is expected to continue growing and serving as a catalyst for innovation in these industries.

Post time: Nov-22-2023