Superabrasives are indispensable tools when it comes to metal grinding and polishing, and cubic boron nitride (CBN) grinding wheels are the leader in this area. CBN grinding wheels stand out for their excellent performance and wide range of applications, becoming one of the indispensable tools in the field of metal processing.

CBN is a synthetic super-hard material, its hardness is second only to diamond. This unique hardness makes CBN grinding wheels perform exceptionally well in metal grinding and polishing processes. Compared with traditional alumina abrasives, CBN grinding wheels have higher wear resistance and heat resistance, allowing them to maintain excellent performance in high-temperature and high-pressure environments.

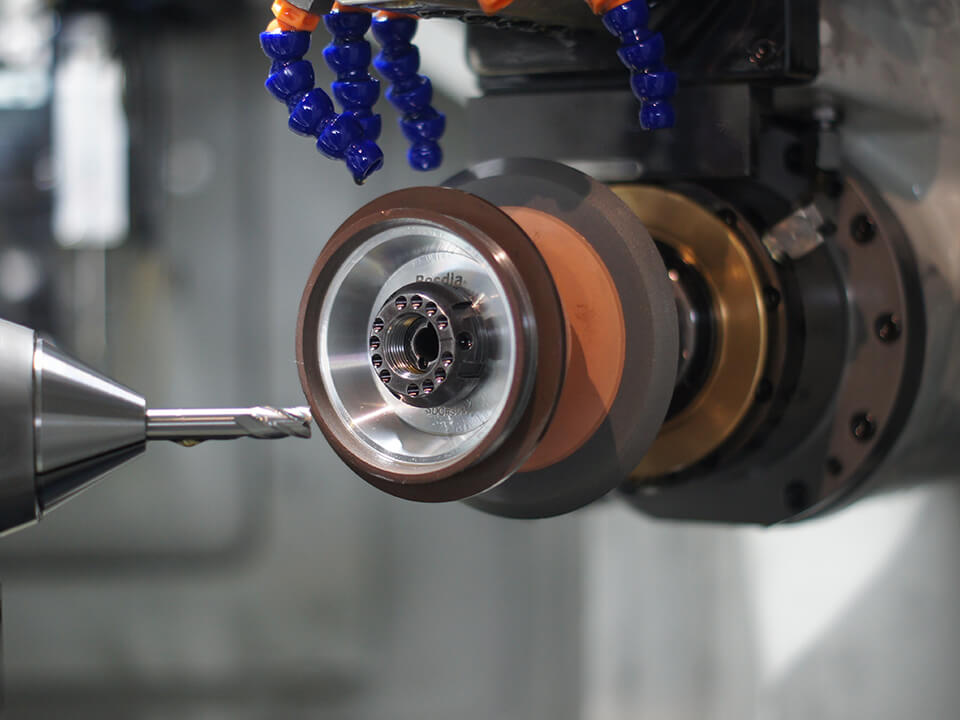

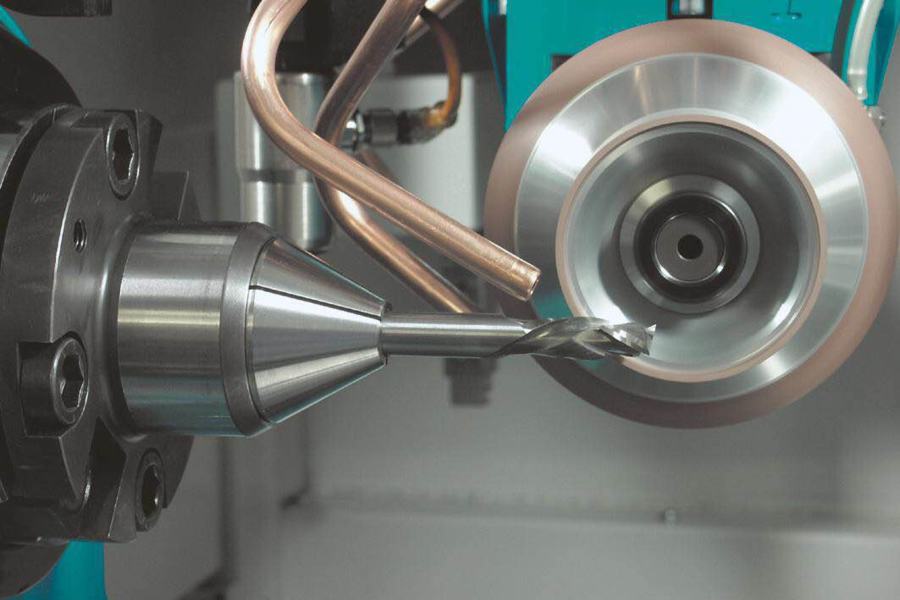

CBN grinding wheel

One of the main advantages of CBN grinding wheels in metal grinding and polishing is their excellent cutting performance. Its hardness and wear resistance allow it to more effectively remove material from metal surfaces and improve processing efficiency. At the same time, CBN grinding wheels can also produce smoother and finer surfaces to meet the processing needs for high precision and high surface quality.

CBN grinding wheel

CBN grinding wheels have demonstrated excellent adaptability in different metal processing applications. It can be used for grinding and polishing various metal materials such as steel, cast iron, high-speed steel, and alloy steel. Whether in automotive parts manufacturing, aerospace or mold manufacturing and other industrial fields, CBN grinding wheels are capable of complex and demanding processing tasks.

In addition, CBN grinding wheels also have a long service life, reducing the frequency of replacing grinding wheels, thereby improving production efficiency and reducing processing costs. Its stable performance makes CBN grinding wheels one of the preferred tools in metal processing plants and manufacturing industries.

Overall, CBN grinding wheels have become star products in the field of metal grinding and polishing due to their excellent hardness, wear resistance, cutting performance and wide applicability. In today's pursuit of efficient, precise and stable processing, CBN grinding wheels have undoub

Our resin bond diamond grinding wheels are designed for quantity grinding, and hard materials grinding in different workshops. Traditional cylindrical grinding wheels are made of Aluminum Oxide, Silicon Carbides and other similar abrasives. If you have not got too much work, and the grinding materials is not too hard, traditional abrasive wheels is fine. But once grinding harder materials above HRC40, especially you have a lot of work to do, the traditional abrasive wheels perform badly on grinding efficiency.

Well, our super-abrasive (diamond / CBN) wheels will help you greatly. They can grind the very hard materials shortly and smoothly. Resin Bond Diamond CBN grinding wheels is the most economy and efficient grinding wheels for grinding materials above HRC 40.

Post time: Jan-09-2024