-

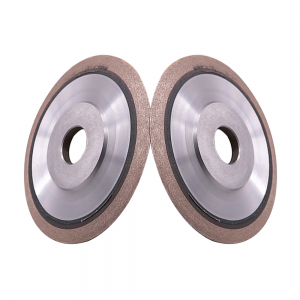

14E1 Metal Bond CBN Grinding Wheel For CNC Broach Grinding Machine For Broaches

Broach grinding wheel is a grinding tool specially designed for use with broaches. Using advanced grinding technology, the broach can be precision ground at the microscopic level to ensure the sharpness and fineness of the blade. Made of high-quality, wear-resistant CBN material, which ensures the durability and stability of the grinding wheel, allowing it to maintain excellent performance over long periods of use. By regularly using the broach to grind the grinding wheel, you can keep the broach sharp and improve work efficiency.

-

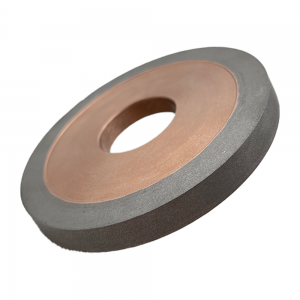

Hybrid Bond Diamond Grinding Wheels For Broach Tool Teeth Grooving

Broach grinding wheel is a grinding tool specially designed for use with broaches.

-

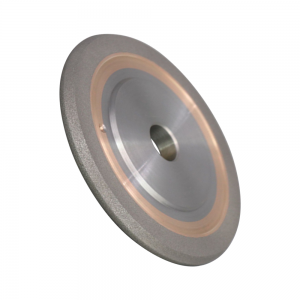

14F1 Hybrid Bond Diamond Grinding Wheel For HSS keyway broach Tool

Broach grinding wheel is a grinding tool specially designed for use with broaches.

-

CBN Grinding Fluting Wheels Resin CBN Broach Grinding Wheel For HSS Keyway Broaches

Broach grinding wheel is a grinding tool specially designed for use with broaches. Using advanced grinding technology, the broach can be precision ground at the microscopic level to ensure the sharpness and fineness of the blade. Made of high-quality, wear-resistant CBN material, which ensures the durability and stability of the grinding wheel, allowing it to maintain excellent performance over long periods of use. By regularly using the broach to grind the grinding wheel, you can keep the broach sharp and improve work efficiency.

-

1A1R Ultra Thin Resin Bond Diamond Cutting Disc For Marble Granite Glass Ceramic

Our comapny developed Super thin 1A1R Diamond and CBN Wheels, which can be used for Cut-off, Cutting, Grooving, Slotting, Dicing and etc. Resin Bond and metal bond are available for different applications. Diameter can be 50mm to 400mm. Thickness is from 0.5mm to 2mm. Grits can be, D151, D181, D126, D107, D91, D76, D64, D46 and others. Cutting material can be: tungsten carbide, ceramic, glass, stone, Gem and gemstones, steel and many other materials.

-

Diamond CBN Grinding Wheel Diamond Tools for Gemstone Lapidary Industry

Ruizuan has rich experience in gem and jewelry grinding and polishing, etc., and has a rich product series to choose from, such as resin gemstone grinding discs, soft resin diamond grinding wheels, electroplated diamond grinding wheels, cutting discs, etc.

-

Resin Bond Bakelite Diamond Grinding Wheel For Circular Saw Blade

RUIZUAN circular saw blade grinding wheels are produced with resin bond and are available in diamond and CBN materials. Grinding wheels come in various shapes, such as flat grinding wheels, bowl-shaped grinding wheels, cylindrical grinding wheels, etc. We have standard regular sizes and models available, as well as custom sizes and models.

-

12A2 Top Grinding Resin Bond Diamond Grinding Wheel for Woodworking Circular Saw Blade Grinding

Resin bond diamond grinding wheel is mainly used for surface grinding ,cylindrical grinding of hand carbide measuring tools ,cutting tools,moulds and also for plunge-cut grinding as well as for grinding. We have much experience in woodworking industry machining.Mainly used for the grinding of circular saw blade, disc saw, chainsaw,bandsaw , etc.

-

Internal Grinding Of Vitrified CBN Inner Wheel Bearing Grinding Machine

Bearing is an important basic parts of all kinds of mechanical equipment, mainly used in metallurgy, wind power, mining machinery, aerospace, automotive parts and so on.Ruizuan provides professional bearing grinding wheels.