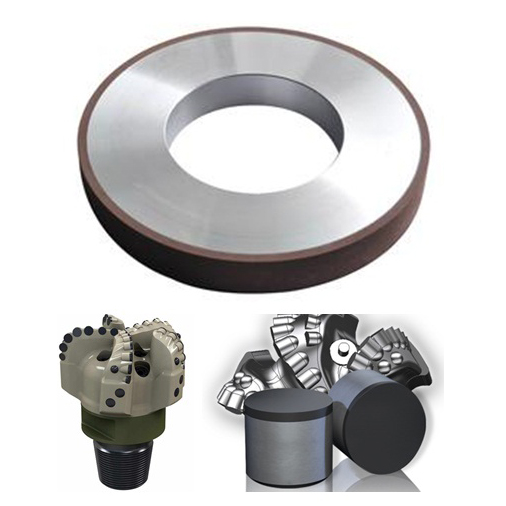

Fast delivery Diamond Dressing – Diamond Grinding Wheels for Hard Ceramic – Ruizuan Detail:

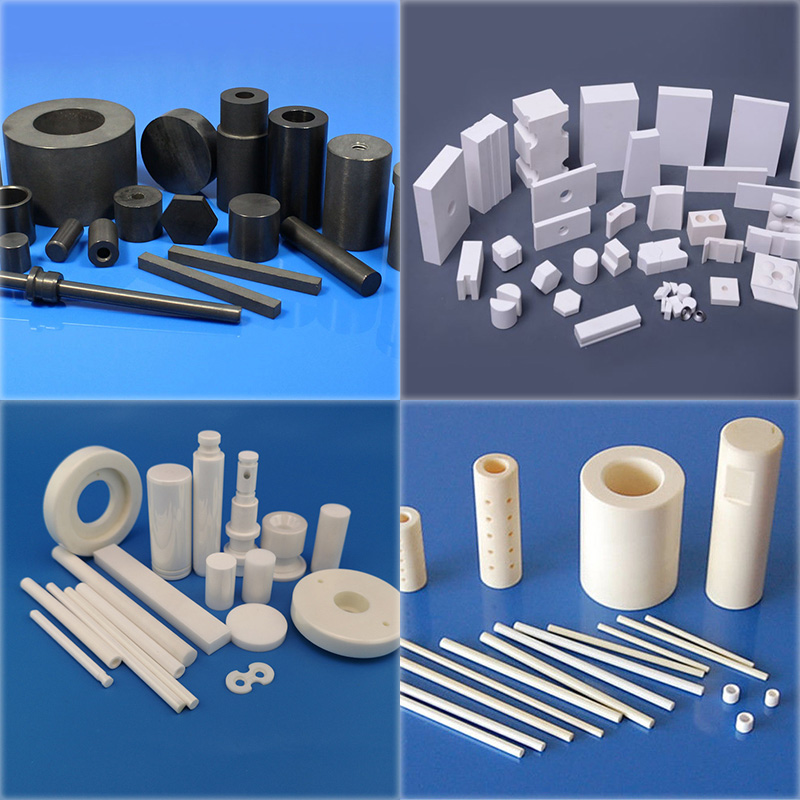

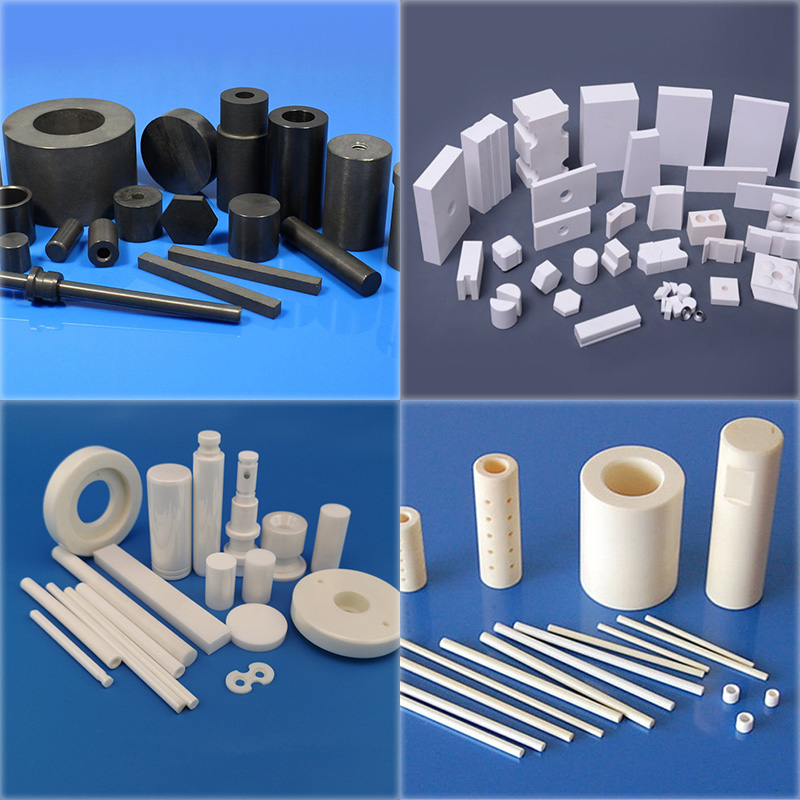

Hard Ceramic is famous for its hardness. They are broadly applied in industrial machine parts, Analytical Instruments, medical parts, semi-conductor, solar energy, automotive, aerospace and etc.

Diamond is the hardest abrasives. A resin bond diamond grinding wheels can free grind Hard ceramic. Diamond can grind all kinds of ceramics, Alumina Ceramic, Zirconia Ceramics, Silicon Nitride CeramicsBoron Nitride Ceramics, Silicon Carbide Ceramics, Boron Carbide Ceramics

Features

1.Fast grinding.

Comparing conventional abrasive wheels, Diamond wheels grind faster. When you do quantity grinding, the fast grinding help you save a lot of time. Saving time and help you make more profits.

2.Excellent finishes

If a grinding wheel is not sharp, chatter waves or lines will appear on workpiece. A sharp diamond grinding wheels will help you solve these problems and bring an excellent surface finish.

3.Cool Grinding

Due to highly efficient grinding, less heat generated. And the aluminum body can help heat spread quickly.

4.Long lifespan

Due to the high hardness of diamond abrasives, Diamond wheels has extra longer lifespan than conventional abrasive wheels.

5.Less dressing

A sharp diamond grinding wheels needs less dressing

Application

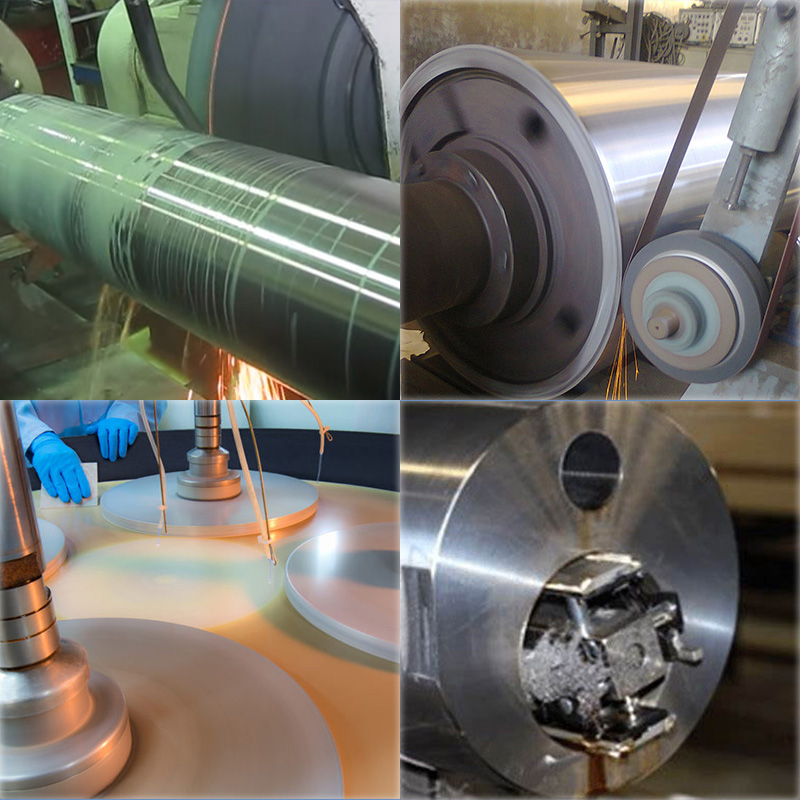

1.Ceramic plate surface grinding

2.Ceramic rod cylindrical grinding

3.Profile grinding of ceramic

4.Cutting wheels for Ceramic cutting or slotting

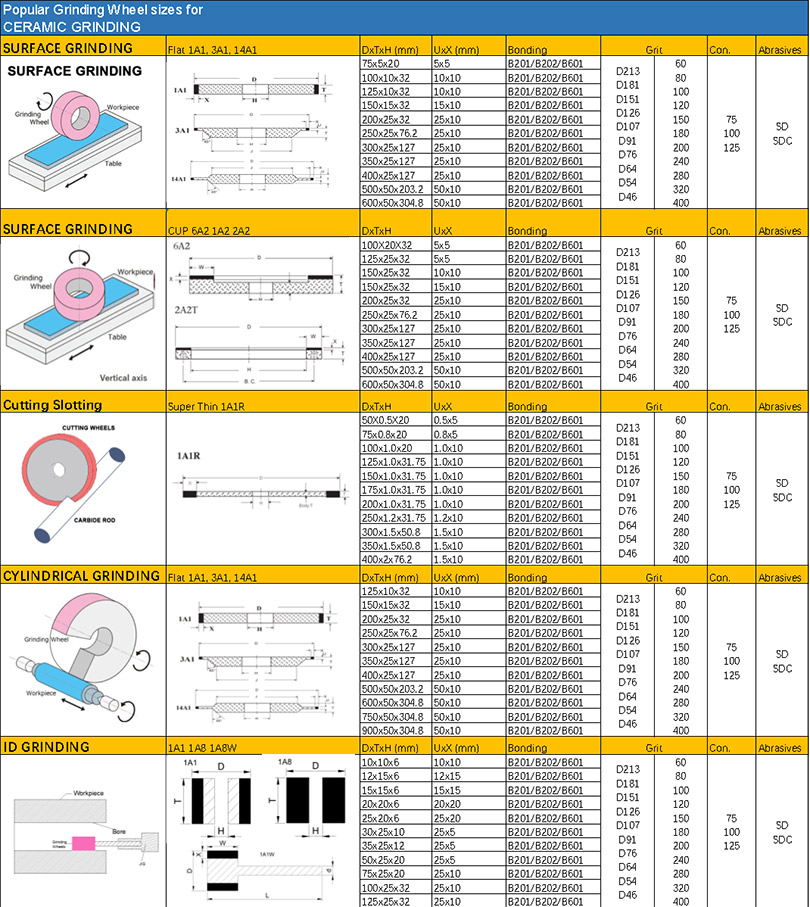

Popular Sizes

FAQ

1. What are your prices?

Our prices are subject to change depending on supply and other market factors. We will send you an updated price list after your company contact us for further information.

2.Do you have a minimum order quantity?

Yes, we require all international orders to have an ongoing minimum order quantity. If you are looking to resell but in much smaller quantities, we recommend you check out our website

3.Can you supply the relevant documentation?

Yes, we can provide most documentation including Certificates of Analysis / Conformance; Insurance; Origin, and other export documents where required.

4.What is the average lead time?

For samples, the lead time is about 7 days. For mass production, the lead time is 20-30 days after receiving the deposit payment. The lead times become effective when (1) we have received your deposit, and (2) we have your final approval for your products. If our lead times do not work with your deadline, please go over your requirements with your sale. In all cases we will try to accommodate your needs. In most cases we are able to do so.

5.What kinds of payment methods do you accept?

You can make the payment to our bank account, Western Union or PayPal: 30% deposit in advance, 70% balance against the copy of B/L.

Product detail pictures:

Related Product Guide:

Now we have highly developed devices. Our items are exported towards the USA, the UK and so on, enjoying a great popularity among the customers for Fast delivery Diamond Dressing – Diamond Grinding Wheels for Hard Ceramic – Ruizuan, The product will supply to all over the world, such as: Uruguay, Norwegian, Ghana, In order to make more people know our products and to enlarge our market, we have devoted a lot of attention to technical innovations and improvement, as well as replacement of equipment. Last but not the least, we also pay more attention to training our managerial personnel, technicians and workers in planned way.

The supplier abide the theory of "quality the basic, trust the first and management the advanced" so that they can ensure a reliable product quality and stable customers.

-

Manufacturer for Cbn Chainsaw Sharpening Wheel ...

-

China Cheap price Diamond Cutting Wheel - Diam...

-

Good Quality Vitrified Bond Grinding Wheel - 1...

-

2022 wholesale price Diamond Cup Wheel - PDC C...

-

Chinese Professional Grinding Wheel For Drill -...

-

One of Hottest for Carbide Cut Off Wheel - Bec...