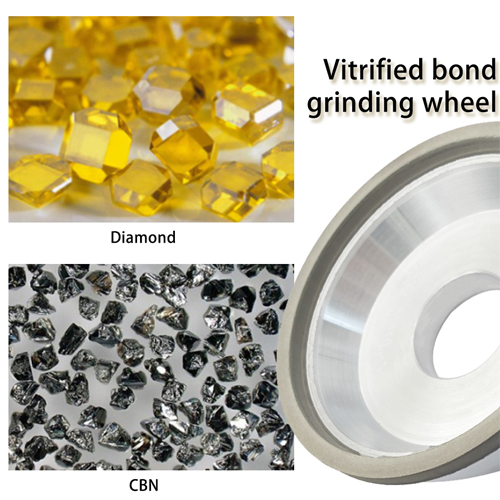

Grinding wheels play a crucial role in various industrial processes, enabling the shaping, cutting, and finishing of materials. However, their effectiveness and lifespan can be significantly impacted by numerous factors. In this blog, we will delve into five key factors that have a significant influence on the life expectancy of grinding wheels. These factors include the type and characteristics of abrasive grains, particle size, coupling, concentration, and bond type.

Understanding the factors that influence the longevity of grinding wheels is crucial for optimizing their performance and cost-effectiveness. By considering the characteristics of abrasive grains, particle size, coupling and concentration, as well as the appropriate bond type, manufacturers and users can extend the lifespan of their grinding wheels and enhance overall productivity. Investing in high-quality grinding wheels and monitoring these influential factors will ultimately result in improved performance and reduced downtime, leading to greater efficiency and success in grinding operations.

Post time: Sep-28-2023