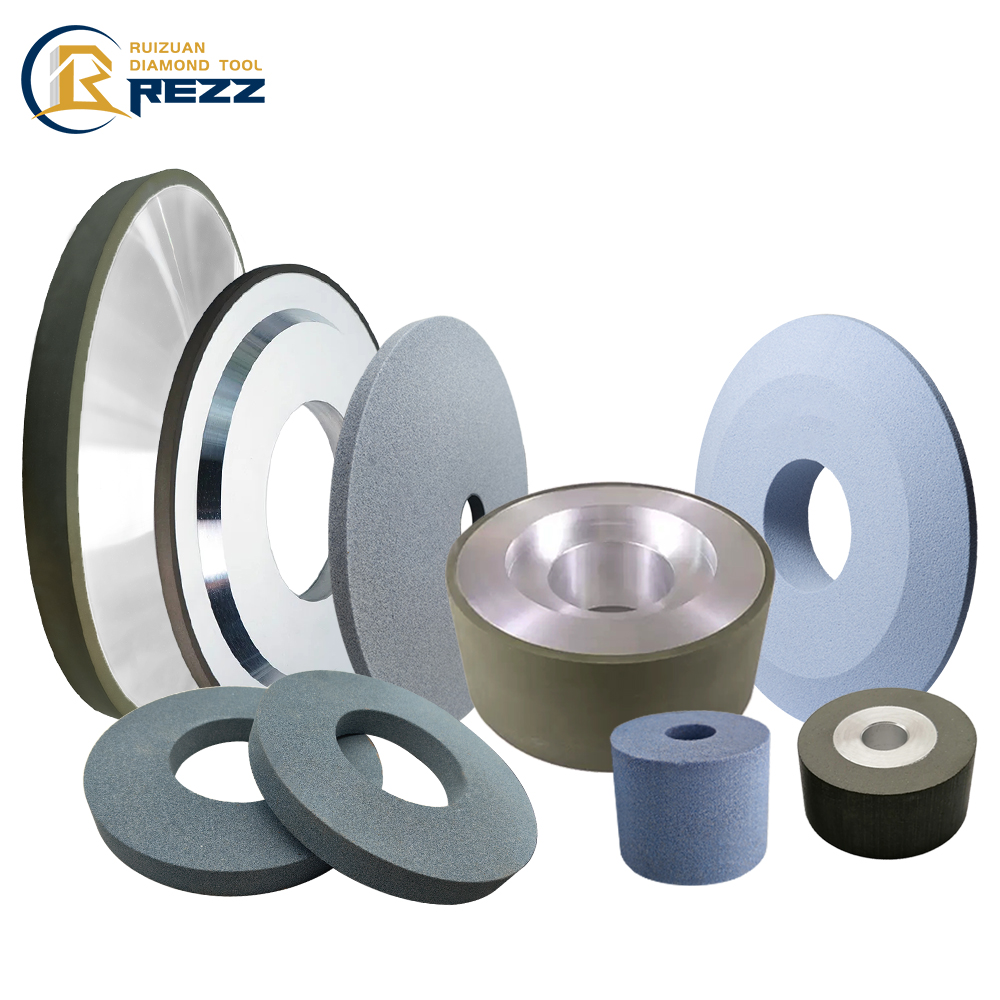

Cylindrical Grinding Wheel

| Product Name | Cylindrical grinding wheel |

| Grinding wheel material | Silicon carbide,Corundum,Aluminum oxide,Diamond,CBN |

| Grinding wheel bond | Vitrified/Resin |

| Cylindrical grinding type | External cylindrical grinding, internal cylindrical grinding, thread grinding, Profile cylindrical grinding,Non-round grinding / contour grinding |

| Grinding workpiece | Long hydraulic cylinders, Auto components, Gears, Roll Cylinders, Tool holders, Journals, crankshafts,chilled cast iron rolls, rubber rolls, copper roll, and granite rolls |

| Wheel size | 50~900 mm,customized |

Cylindrical Grinding Methods

Cylindrical Grinding wheel applications would be the most commonly seen, Most of the time, the job ideal for cylindrical grinding would be symmetrical in shape to be held between two opposite centers , Its applications include , Long hydraulic cylinders, Auto components, Gears, Roll Cylinders, Tool holders, Journals, crankshafts and many more. These include heavy metal removal to super fine glass finishes.

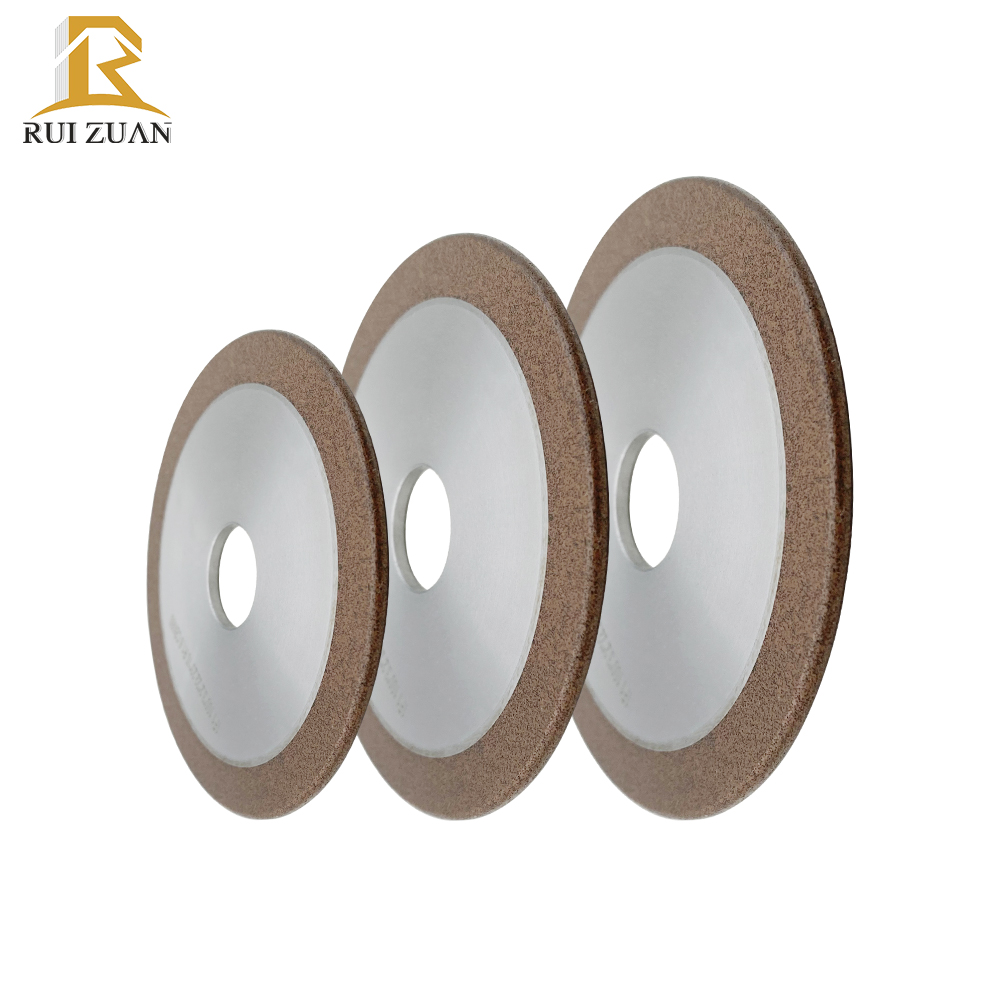

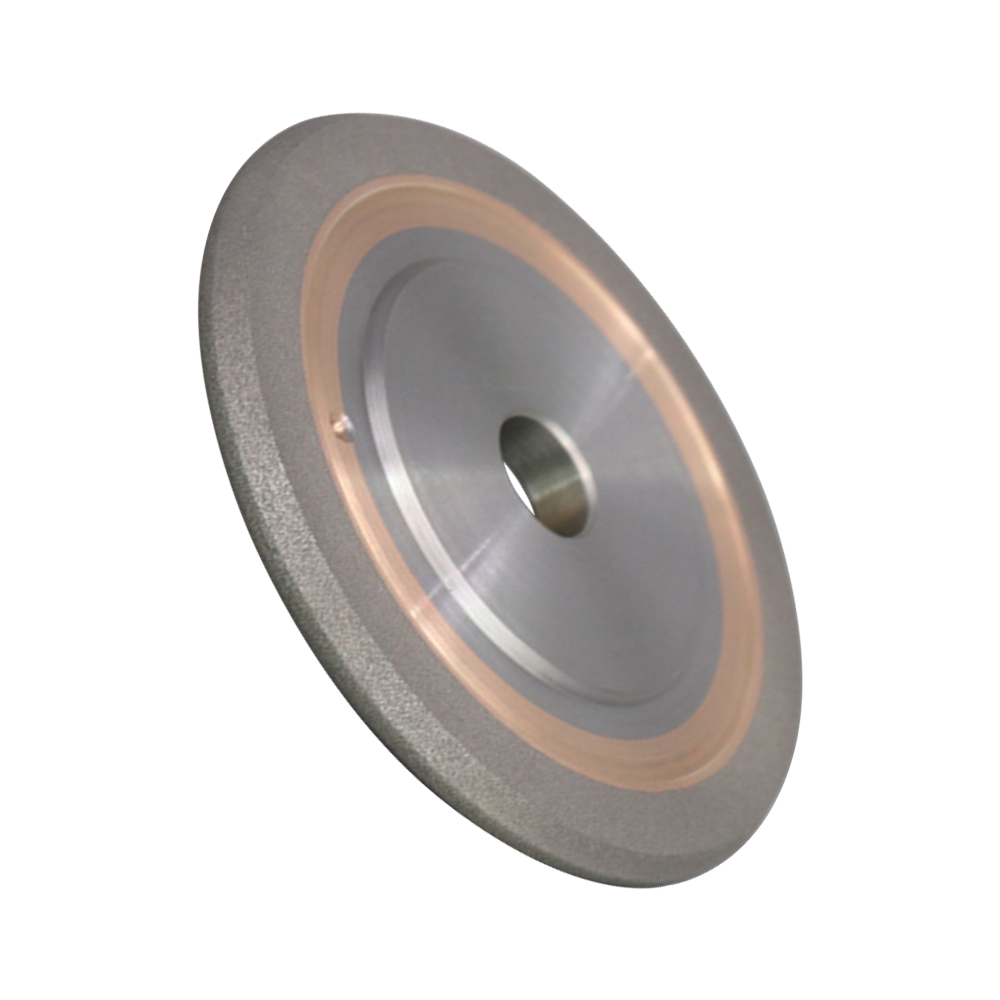

1.Diamond Cylindrical Grinding Wheels mainly used for grinding PCD, tungsten carbide, ceramics, magnetic material, stainless steel bar

2.CBN wheels are mainly used for grinding steel materials, while diamond wheels are used for the cylindrical grinding of tungsten steel, ceramics, and other materials.

3.Corundum grinding wheels are used for hardened or non-hardened steel rolls. Silicon carbide grinding wheels are used for chilled cast iron rolls, rubber rolls, copper roll, and granite rolls. For steel rolls with different materials, the corundum grinding wheel should be matched to obtain high grinding precision and surface quality.

CNC Cylindrical grinding machines:

Okuma,Toyoda,Studer,Junker,Kellenberger,SHARP,Landis,Bryant,Supertec,Cincinnati,Heald,Okamoto

Universal Cylindrical Grinding machine

Cincinnati, Supertec,Landis, Brown & Sharpe, Toyoda, Okuma, Jones & Shipman, Shigiya, Studer, TOS Hostivar, Doosan, Okamoto, and Fermat

-

Vitrified CBN Grinding Wheel for Machining Arti...

-

CBN 11v9 grinding wheel 6 Inch Resin Bond Grind...

-

1F1 Resin Bond Diamond CBN Grinding Wheel for C...

-

14F1 Hybrid Bond Diamond Grinding Wheel For HSS...

-

High Efficiency Diamond & CBN Metal Bonded...

-

6A2 11A2 Bowl-shape Resin Bond Diamond CBN Grin...