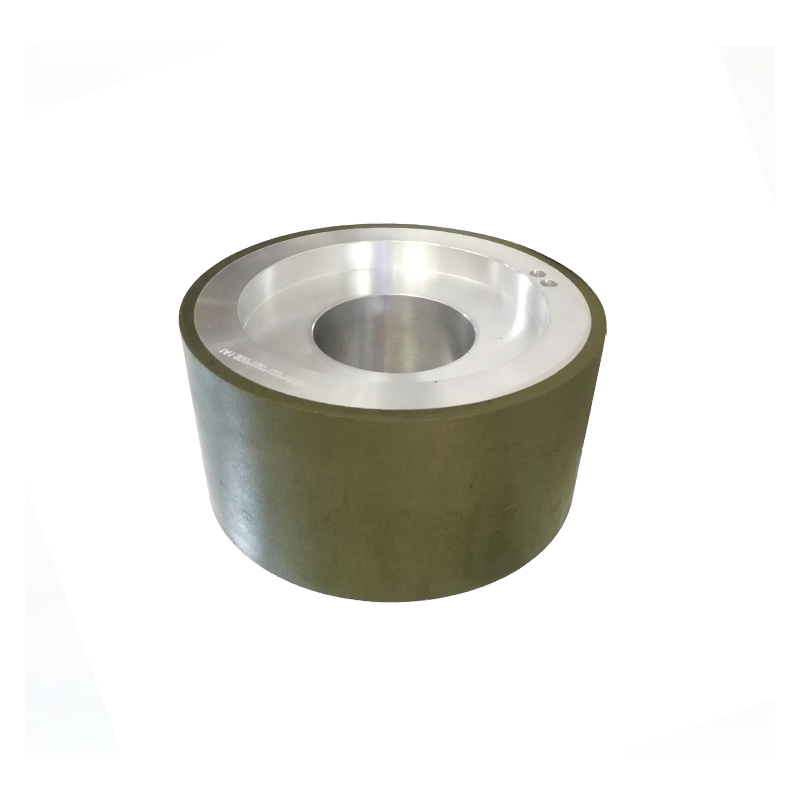

Resin bond diamond grinding wheels are suitable for carbide molds and dies, hardened steel molds and dies, and punches.

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||

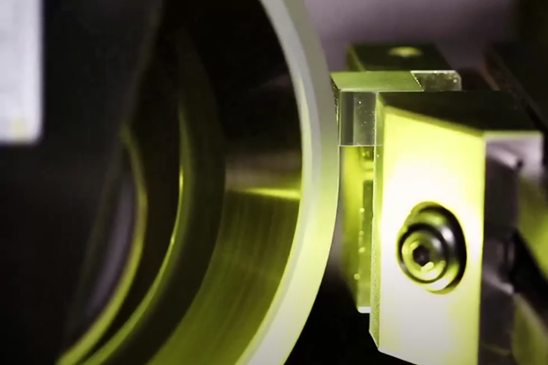

1.Due to its self-sharpening, resin bond wheel is easy to use and is suitable for roughing – finishing.

2. Due to moderate abrasive holding strength and wear-resistance, this wheel is suitable for roughing with free cutting.

3.Due to elasticity, this wheel using fine grits is suitable for finishing.