Mould Die Grinding Wheel

For mould and die making, grinding wheels must be carefully selected based on the workpiece material, desired finish, and grinding process. Key factors in selection include the abrasive type, grit size, bond, and grade. Specialized superabrasives like diamond are often used for precision grinding of hard tool steels and carbides

|

||||||||||||||||||||||

Advantage

1.Due to its self-sharpening, resin bond wheel is easy to use and is suitable for roughing – finishing.

2. Due to moderate abrasive holding strength and wear-resistance, this wheel is suitable for roughing with free cutting.

3.Due to elasticity, this wheel using fine grits is suitable for finishing.

-

Alumina Abrasive Grinding Wheel for Artificial ...

-

Aluminium Oxide Skate Sharpening Wheel Abrasive...

-

PVA Sponge Wheel Centerless Grinding Wheel PVA ...

-

Valve Seat Abrasive Grinding Wheel General Purp...

-

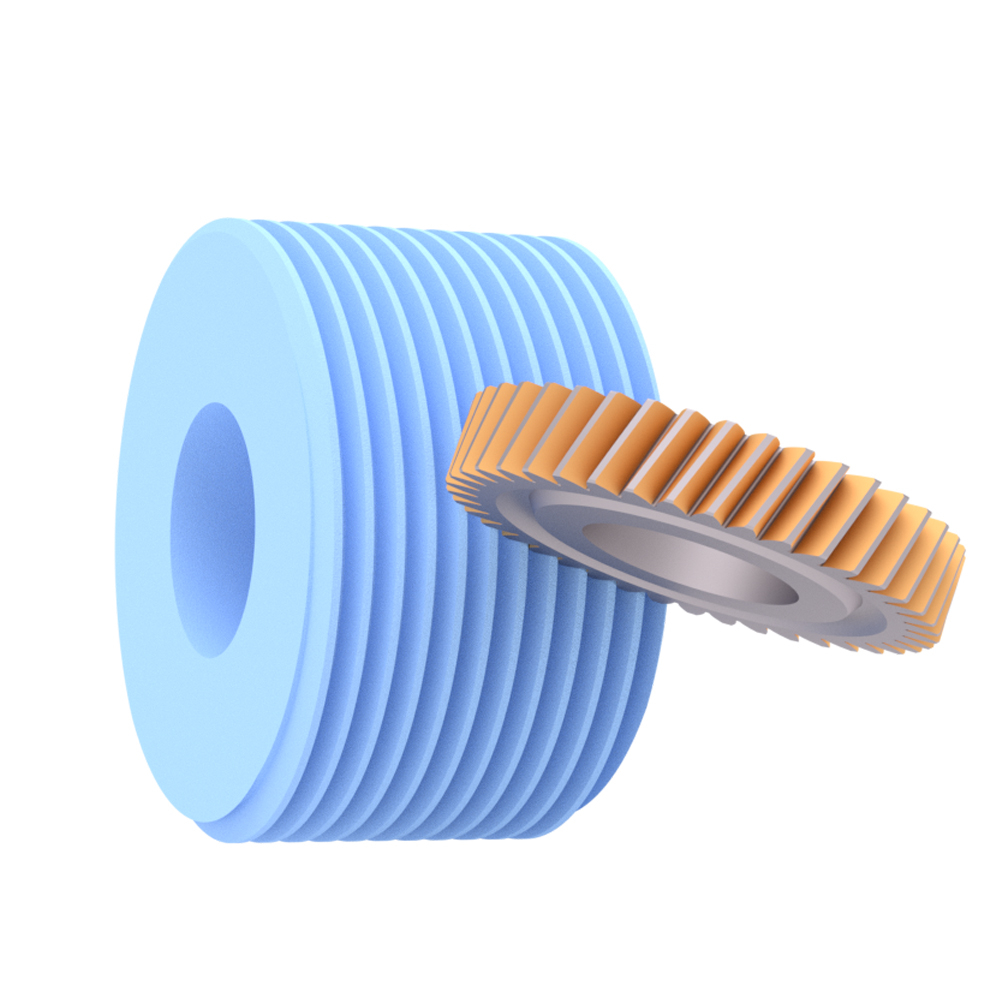

Abrasive Wheels Whole Seller Worm Profile Grind...

-

Black Silicon Carbide Grinding Wheel Resin Grin...