Injection nozzle grinding wheels often made of CBN or diamond, are used in conjunction with grinding machines to restore the nozzle's sealing surfaces and valve seats. The grinding process removes imperfections and wear, allowing for proper fuel delivery and combustion.

|

Advantages of vitrified CBN internal grinding wheel for Fuel Injector

1.Longer dressing interval

2.Consistent grinding performance

3.Highly precise wheel shape including coolant hole and slots

2.Consistent grinding performance

3.Highly precise wheel shape including coolant hole and slots

Application of virtrified CBN grinding wheel

* Automotive Parts

Fuel injection bore

Fuel injection seat

Connectong rod bore

Gearwheels, transimission gear

-

1V1 Electroplated Taper Edge Diamond CBN Grindi...

-

9A3 Resin Bond Diamond CBN Grinding Wheel for E...

-

6A2 diamond & cbn vitrified bonded wheel F...

-

Diamond CBN Grinding Wheel Diamond Tools for Ge...

-

6A2T LED Substrate Metal Bond Back Grinding Whe...

-

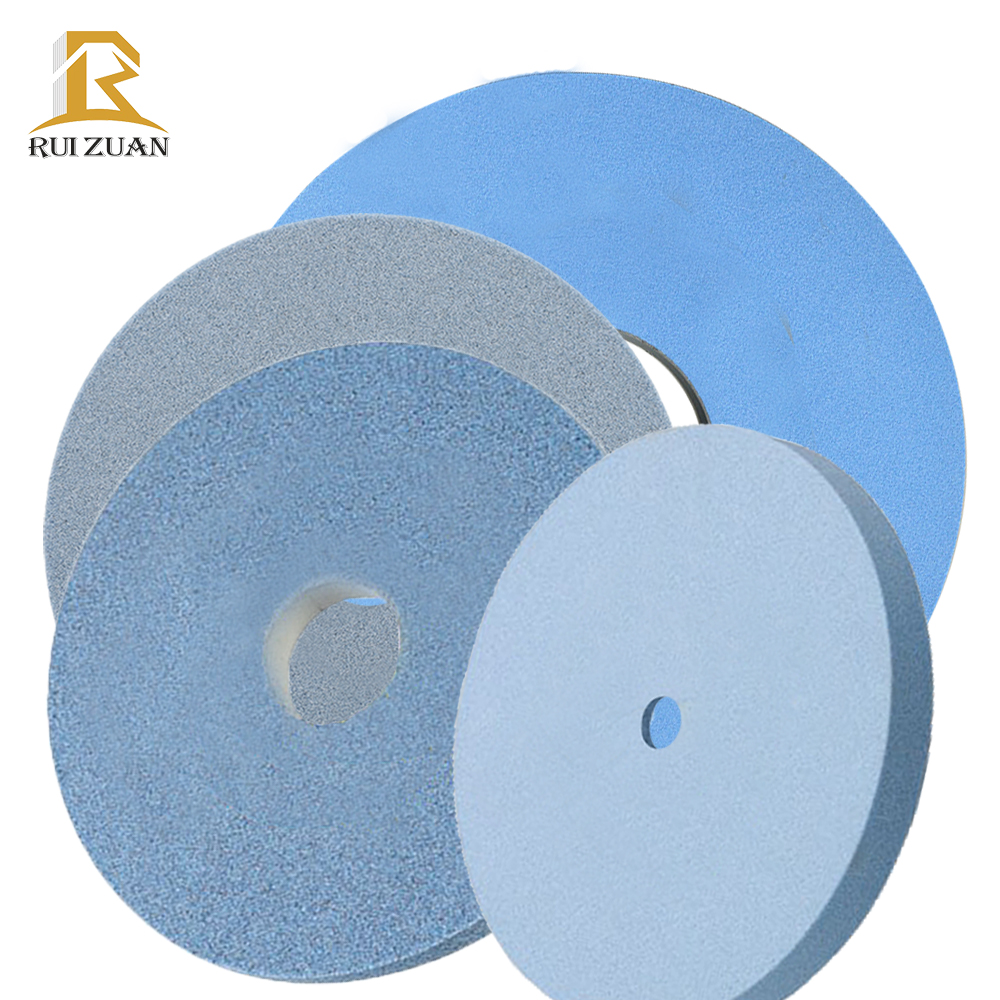

SG Ceramic Grinding Wheels Blue Grinding Wheel ...