Samples

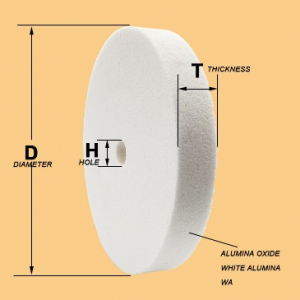

Parameters

| Specification | DiameterD | ThicknessT | Hole DiameterH | Available Abrasives |

| 4"x1/2"x1/2" | 4"-100mm | 1/2"-12.7mm | 1/2"or customized | Corundum:A,WA,PA,AA,SA,

MA,AWA, ASA Silicon carbide:C,GC,GSC,BC Diamond:D CBN:B |

| 5"x1"x1/2" | 5"-120mm | 1"-25.4mm | 1/2"or customized | |

| 6"x1"x1/2" | 6"-150mm | 1"-25.4mm | 1/2"or customized | |

| 6“x1.5"x1-1/4" | 6"-150mm | 1.5"-38.1mm | 1-1/4"or customized | |

| 8"x1”x5/8" | 8"-200mm | 1"-25.4mm | 5/8"or customized | |

| 8"x1.5"x5/8" | 8"-200mm | 1.5"-38.1mm | 5/8"or customized |

Structures

RZ develops different grinding wheels for different applications. Generally, the grinding wheels are classified according to the abrasive types. There are mainly 4 kinds of abrasives, corundum, silicon carbide, synthetic diamond, CBN. They are available at our company.

Application

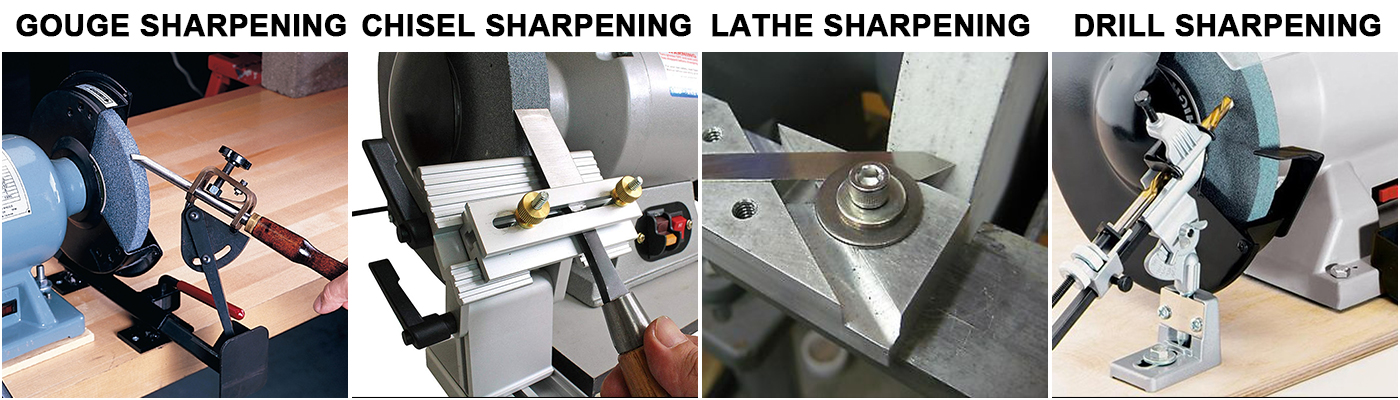

ur grinding wheels provide metal removal, deburring, shaping, polishing and sharpening needs. Available to fit many sizes and specification of machines.

Our variety of abrasive selection meets the application need for HSS high speed tool steels, carbon steel, non-ferrous metals and tungsten carbide tooling. They can be drill bits, lathes, inserts woodturning gouges, wood chisels, wood knife blades, saw blades, knives and so on.

Features

1. Selected abrasives keep our wheel quality.

2. The weld seam is thin, the penetration depth is large, the taper is small, the precision is high, the appearance is smooth, flat and beautiful.

3. The amount of thermal deformation is small, and the melting zone and the heat-affected zone are narrow and deep.

4. High cooling rate, which can weld fine weld structure and good joint performance.

5. Laser welding has less consumables and long service life.

6. Easy operating need no training, more environmentally friendly.

Details

FAQ

1. What are your prices?

Our prices are subject to change depending on supply and other market factors. We will send you an updated price list after your company contact us for further information.

2.Do you have a minimum order quantity?

Yes, we require all international orders to have an ongoing minimum order quantity. If you are looking to resell but in much smaller quantities, we recommend you check out our website

3.Can you supply the relevant documentation?

Yes, we can provide most documentation including Certificates of Analysis / Conformance; Insurance; Origin, and other export documents where required.

4.What is the average lead time?

For samples, the lead time is about 7 days. For mass production, the lead time is 20-30 days after receiving the deposit payment. The lead times become effective when (1) we have received your deposit, and (2) we have your final approval for your products. If our lead times do not work with your deadline, please go over your requirements with your sale. In all cases we will try to accommodate your needs. In most cases we are able to do so.

5.What kinds of payment methods do you accept?

You can make the payment to our bank account, Western Union or PayPal: For big orders, partial payment is also acceptable.