Product Description

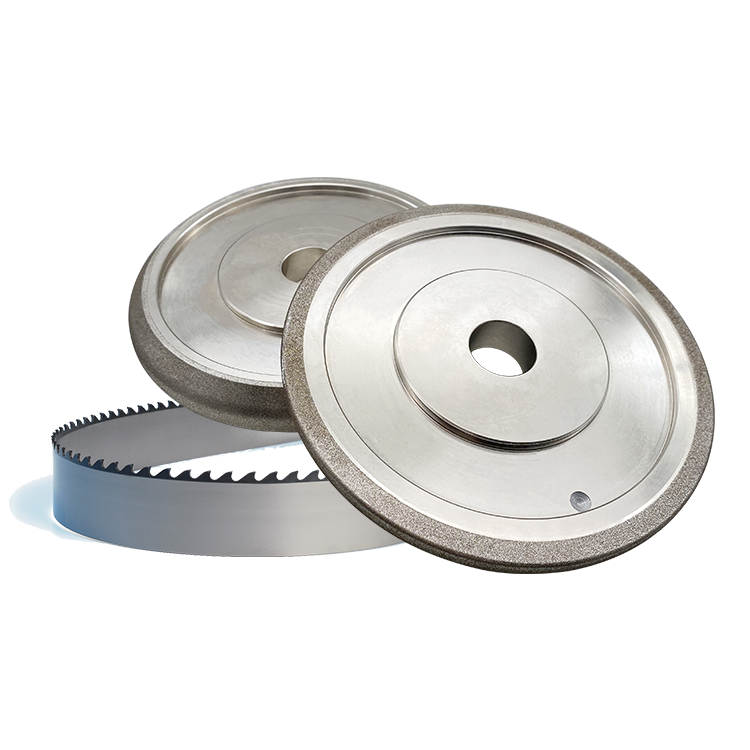

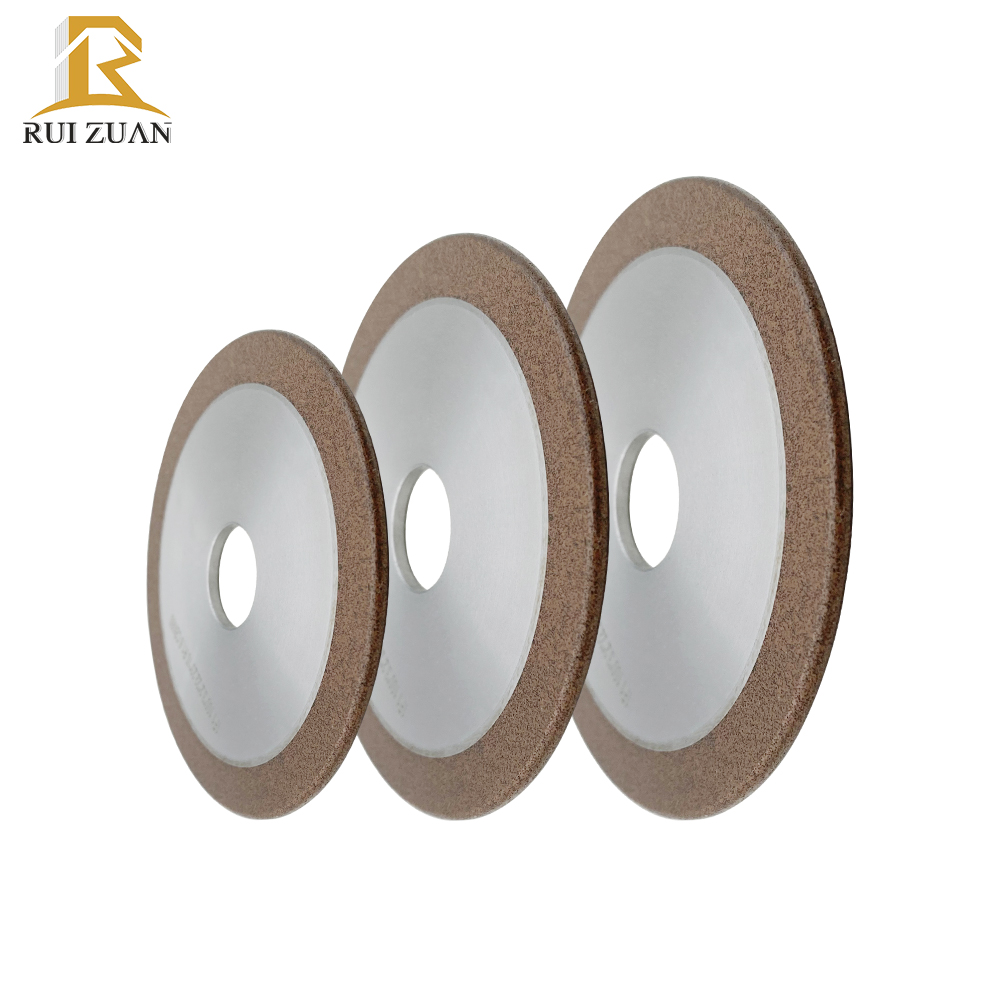

The electroplated grinding wheels have characteristics of high grain density ,sharp grinding ,high efficiency, good precision ,without dressing etc. Suitable for special complicated profile , super-thin ,especially small and other form grinding which have strict requirement on geometry shape and dimension.

Welcome to wholesale & OEM & ODM.

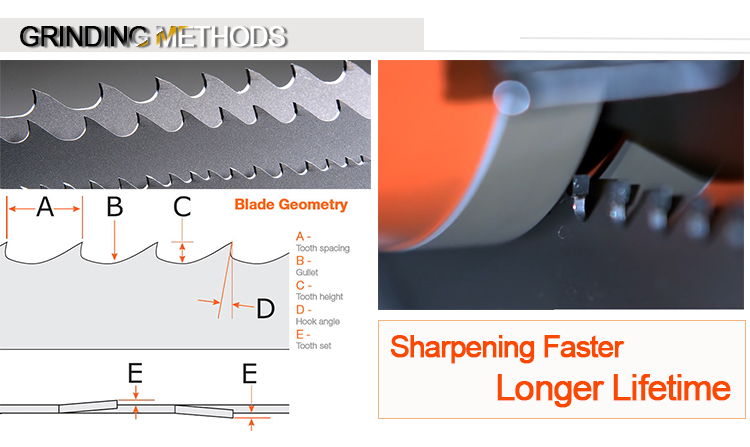

Advantages of our CBN bandsaw blade grinding wheel

Less heat generation, higher grinding efficiency and longer life, more suitable for grinding band saws.

The steel body is strong and durable and will never deform. One grinding wheel can help you grind more than 1000 bandsaws.

High quality steel body and selected CBN abrasives, the quality equals or better than origional brand wheels

Parameters

|

||||||||||||||||||||||||||||||||||||||||||||||||

Application

Applicable machine brand: Wright, Vollmer, Wood-Mizer, Colonial Saw, Amada, Cooks, WOODLAND MILLS, TimberKing, WESTRON, Holzmann, NEVA, ISELI, Hud-Son, ZMJ, YOKEN.

Saw blade applicable: Simonds, Lenox, Wood-Mizer, Dakin-Flathers Ripper, Timber Wolf, Lenox Woodmaster, Munkfors, Fenes, Armoth, Ro-Ma, Wintersteiger, MK Morse, Forezienne, Bacho, Pilana, Disston.

FAQ

1. What are your prices?

Our prices are subject to change depending on supply and other market factors. We will send you an updated price list after your company contact us for further information.

2.Do you have a minimum order quantity?

Yes, we require all international orders to have an ongoing minimum order quantity. If you are looking to resell but in much smaller quantities, we recommend you check out our website

3.Can you supply the relevant documentation?

Yes, we can provide most documentation including Certificates of Analysis / Conformance; Insurance; Origin, and other export documents where required.

4.What is the average lead time?

For samples, the lead time is about 7 days. For mass production, the lead time is 20-30 days after receiving the deposit payment. The lead times become effective when (1) we have received your deposit, and (2) we have your final approval for your products. If our lead times do not work with your deadline, please go over your requirements with your sale. In all cases we will try to accommodate your needs. In most cases we are able to do so.

5.What kinds of payment methods do you accept?

You can make the payment to our bank account, Western Union or PayPal: For big orders, partial payment is also acceptable.

-

6A2 diamond & cbn vitrified bonded wheel F...

-

Vitrified Bond Superabrasive Diamond CBN Grindi...

-

1F1 Resin Bond Diamond CBN Grinding Wheel for C...

-

High Efficiency Metal Bond CBN Grinding Wheel G...

-

CBN 11v9 grinding wheel 6 Inch Resin Bond Grind...

-

6A2 11A2 Bowl-shape Resin Bond Diamond CBN Grin...