Product Description

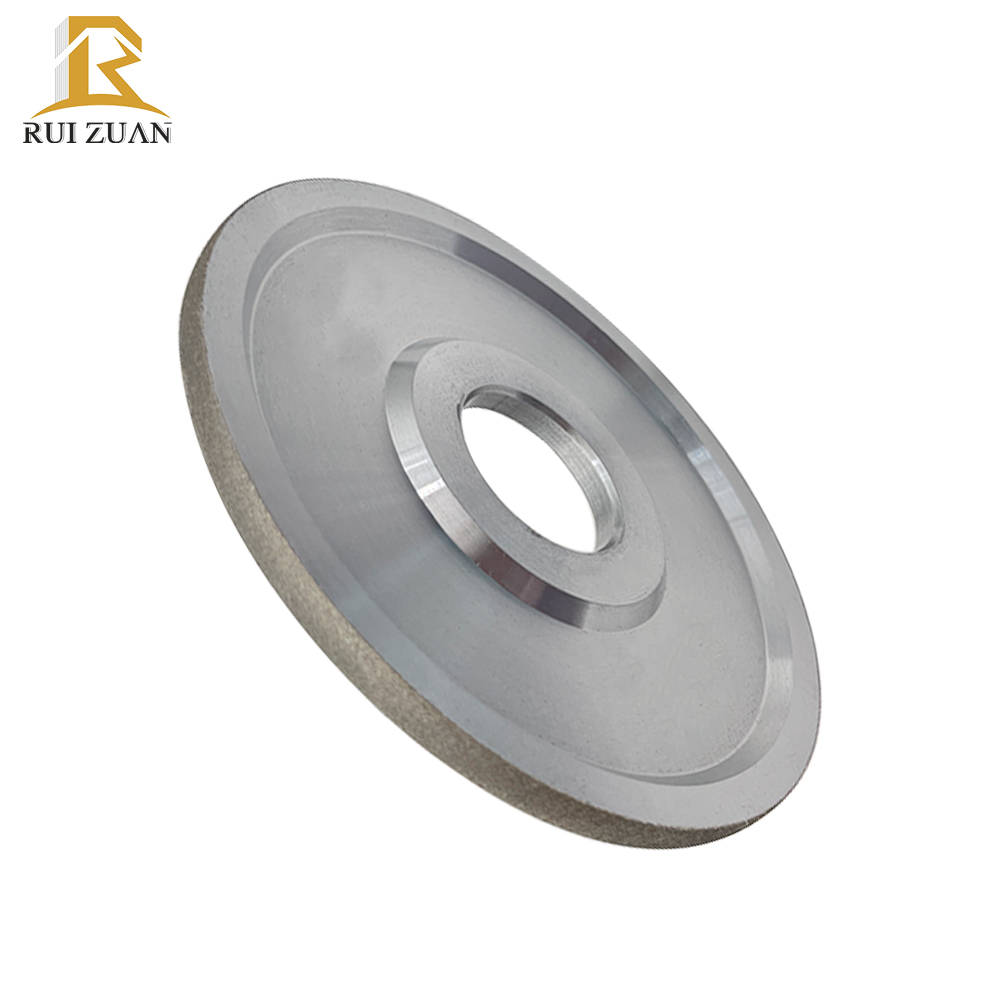

Product Features.

3. Long life. Much longer life than traditional abrasive wheels

4. High viscosity,the sand not easy to drop

5. Well balanced each wheels

6. Outter diameter is no change from start to end

7. No dust coming out when sharpening and grinding

8. Customized design is available

Parameters

|

||||||||||||||||||||||||||||||||||

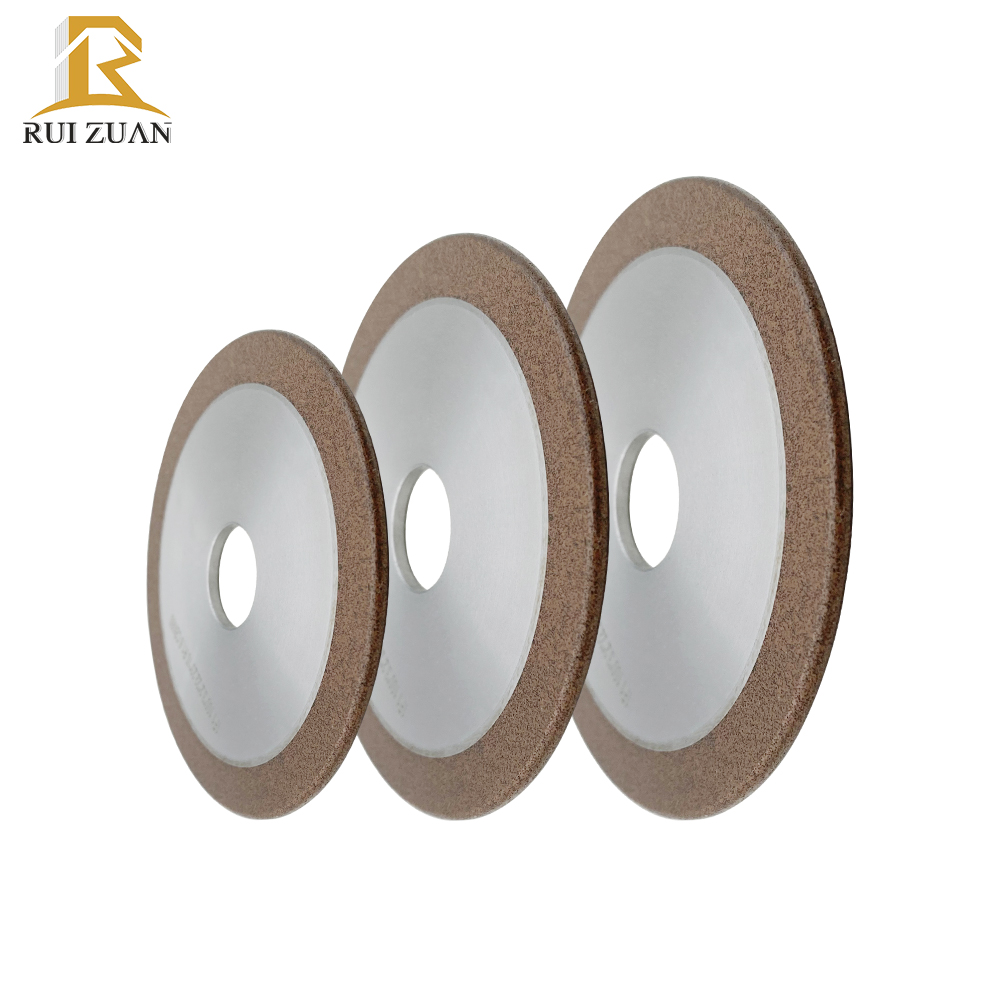

Selection of grinding wheel elements.

2. when doing the rough grinding ,in order to increase the productivity, the coarse grit, soft grinding wheel should be chosen,In order to improve the surface quality of the work piece during accurate grinding , the fine grit ,hard grinding wheel should be chosen.

3.the large area of grinding or thin-walled work piece grinding should choose the coarse grit, soft grinding wheel. This wheel is not easy to plug, the surface of the work piece is not easy to burn, the work piece is not easy to deformation.

4. form grinding process to select the fine grit, the small organization, and the hard grinding wheel to maintain the profile of the grinding wheel.

Application

FAQ

1. What are your prices?

Our prices are subject to change depending on supply and other market factors. We will send you an updated price list after your company contact us for further information.

2.Do you have a minimum order quantity?

Yes, we require all international orders to have an ongoing minimum order quantity. If you are looking to resell but in much smaller quantities, we recommend you check out our website

3.Can you supply the relevant documentation?

Yes, we can provide most documentation including Certificates of Analysis / Conformance; Insurance; Origin, and other export documents where required.

4.What is the average lead time?

For samples, the lead time is about 7 days. For mass production, the lead time is 20-30 days after receiving the deposit payment. The lead times become effective when (1) we have received your deposit, and (2) we have your final approval for your products. If our lead times do not work with your deadline, please go over your requirements with your sale. In all cases we will try to accommodate your needs. In most cases we are able to do so.

5.What kinds of payment methods do you accept?

You can make the payment to our bank account, Western Union or PayPal: For big orders, partial payment is also acceptable.

-

Eelctroplated Diamond CBN wheels for bench grinder

-

CBN 11v9 grinding wheel 6 Inch Resin Bond Grind...

-

CBN Grinding Wheels For Chain Saw Teeth Sharpening

-

Electroplated CBN Grinding Wheel For Speed Skat...

-

1F1 Resin Bond Diamond CBN Grinding Wheel for C...

-

CBN Grinding Wheel Electroplated cbn wheel for ...